Causes

- Deposit of entrained adhesive mist

- Roll surface not sufficiently anti-adhesive

- Roll surface cannot be sufficiently cleaned

Effects

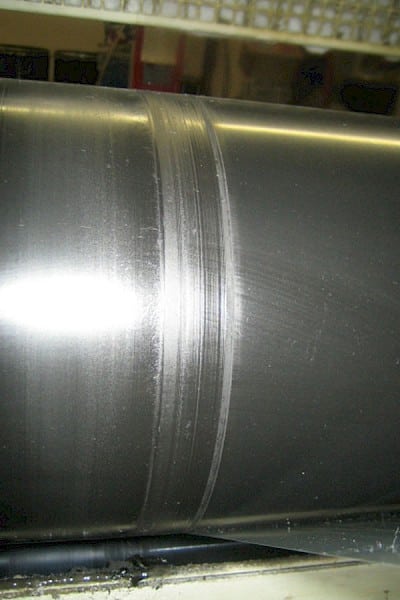

- Adhesive buildup on roll coating

- Impression roll is damaged at the edge of the product web

- This restricts the working widths that are possible in the future

During adhesive application, adhesive mist is carried from the application unit to the laminating unit. Adhesive residue / adhesive mist remains on the roller surface of the laminating press outside the web width. The tackiness of the deposited adhesive mist increases over time. As a result, tiny pieces tear out of the coating of the impression roller. This effect increases over time. Wider products can no longer be run.