Special Roll Coatings

Developed for the most demanding applications

We work on each request to meet the customer’s requirements in the best possible way and are always happy to face new challenges with commitment and creativity. The MITEX special coatings presented here are examples of the results of such challenges and convince with the exceptional product properties of our developments.

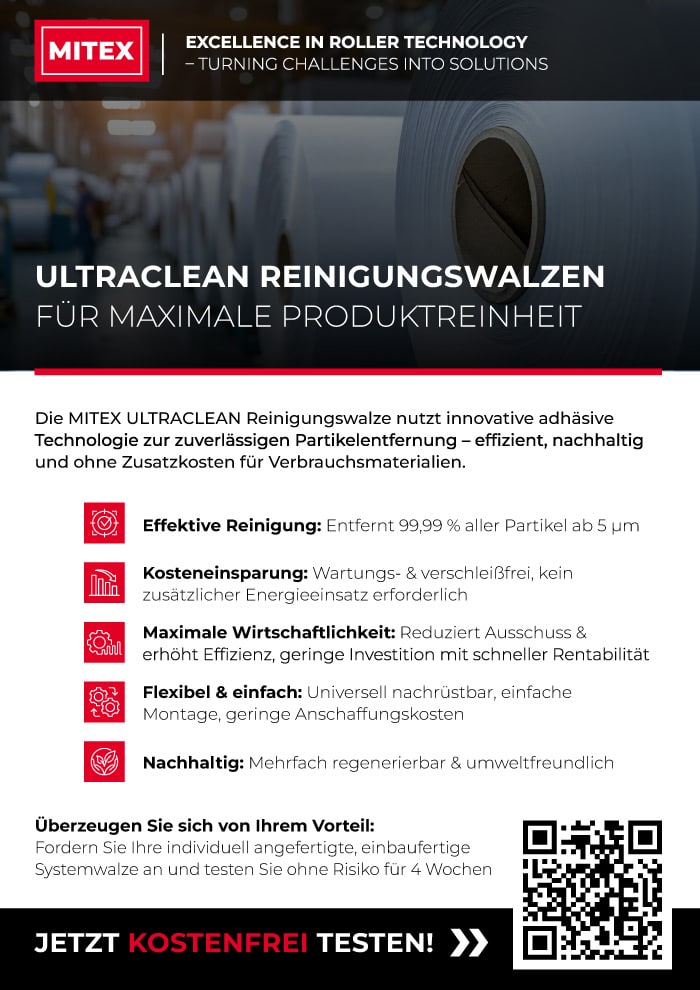

MITEX UltraClean

Foreign bodies in the substrate are problematic in any demanding production and inevitably lead to complaints or internal rejections. Conventional web cleaning systems require either energy-intensive media such as compressed air or environmentally harmful and expensive consumables. With the ULTRACLEAN cleaning roller, MITEX offers a cost-effective and sustainable alternative which can completely remove foreign bodies down to a diameter of 5 µm.

The roller can be flexibly and easily retrofitted and continuously cleaned by a violet, even more adhesive version. The stickiness of the coating is permanently sustainable and can be easily restored with warm soapy water.

The coating of complex, sophisticated structures with roll coating machines is made possible by the precisely adjustable soft coating DECOTECH. The special colour spreading of the polymer from MITEX achieves a convincing coating result. The hardness can be adjusted in a defined way between 5 and 40 Shore A and allows the coating of deep profiles.

The coating is successfully used in the furniture and flooring industry (PVC / wood) as well as for special applications.

MITEX DecoTech

MITEX PTECH

The PTECH coating ensures homogeneous film and foil embossing without structural deviations – constant, stochastic, and reliable. Defined roughness levels enable precise matting and open up new process windows for demanding embossing applications. The regrindable surface guarantees long-term consistent results, making PTECH an efficient and durable solution for film matting and embossing processes.

The NEOSANEX product series was developed and tested specifically for applications in the medical and food industries. These coatings enable the safe use of rollers and components in direct or indirect contact with food and medical products. NEOSANEX sets new standards for certified production processes and ensures maximum safety and quality in demanding applications, from plastic articles with food contact to plasters and blister packs.

MITEX NEOSANEX

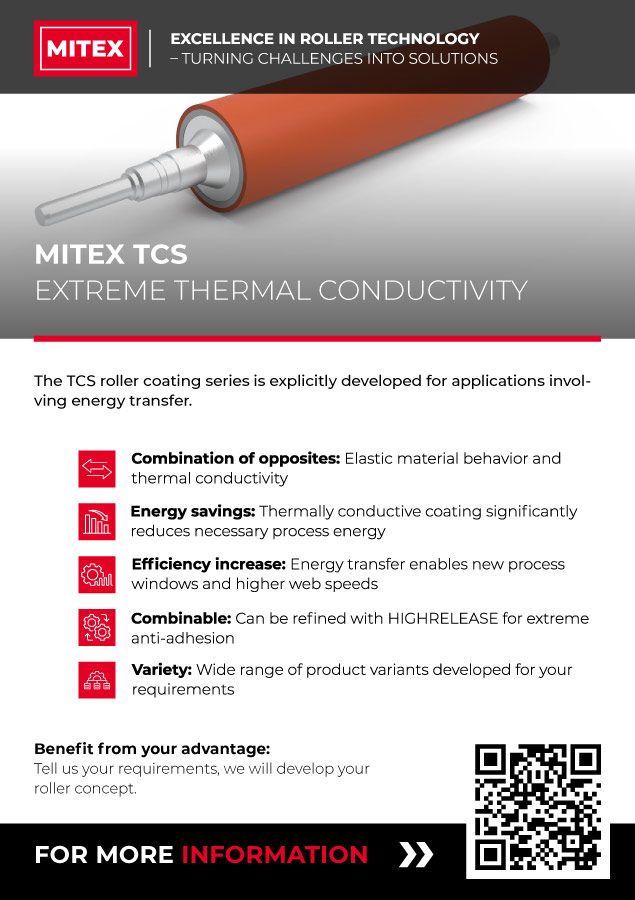

MITEX TCS

The TCS product series is designed for applications with extreme energy transfer. With up to four times higher thermal conductivity, TCS sets new benchmarks for cooling and heating rollers, reliably withstanding high process temperatures. The coating combines anti-adhesive properties with precise grindability, ensuring stable and efficient performance in embossing counter rollers, extrusion calibration rollers, curtain coating, lamination, and adhesive application.

MITEX has been setting benchmarks for rollers with extremely anti-adhesive coatings for years and is a leader in the production of roll coatings for laminating applications as well as extrusion processes. However, in order to use this high-performance coating economically for web guide rolls as well, a new process had to be designed following a corresponding customer inquiry.

The product, MITEX HIGHRELEASE, allows the modified coating to be used economically for simple web guide rolls where other coatings available on the market did not allow permanent anti-adhesion. HIGHRELEASE is also available in an electrically conductive version for use in any film application with adhesive substrates.

MITEX HIGHRELEASE

MITEX SILTECH

The SILTECH silicone coatings provide a wide range of materials to meet various demanding process requirements. They combine high temperature resistance with excellent release properties, ensuring reliable results even under challenging conditions. With strong mechanical properties and resistance to oils, greases, and UV radiation, SILTECH rollers are versatile for applications such as cast film production, hot-melt extrusion, laminating, and embossing.

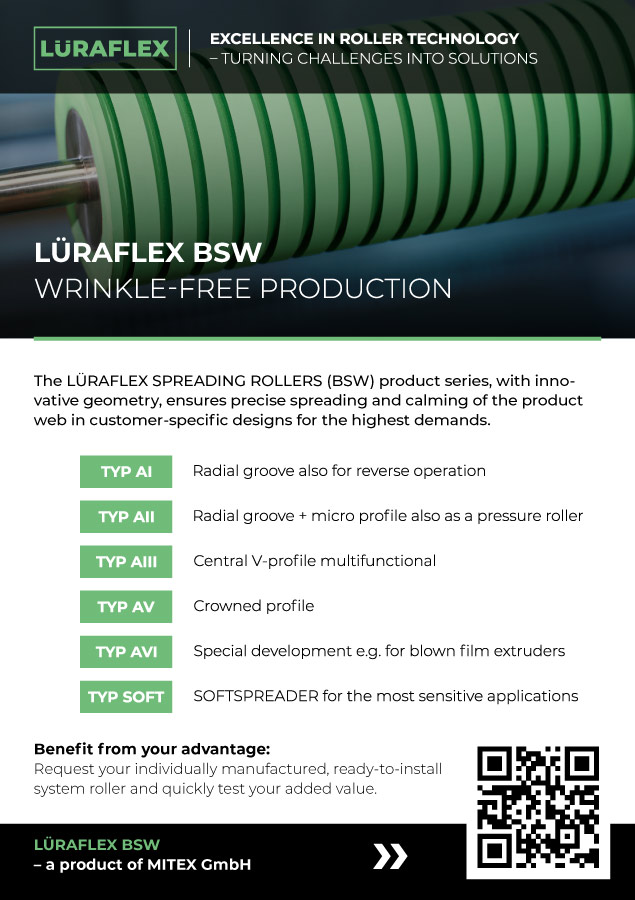

The LÜRAFLEX BSW spreader rollers ensure wrinkle-free webs and effective web stabilization – even at high speeds and low web tensions. With different roller designs available, they can be perfectly adapted to specific production requirements. Proven worldwide for decades, BSW rollers provide reliable, maintenance-free spreading performance, ensuring smooth and material-friendly processing across a wide variety of substrates.

LÜRAFLEX BSW

LÜRAFLEX MULTILAYER

The LÜRAFLEX MULTILAYER rollers ensure reliable processes by combining varying hardness levels in a patented sandwich design (DE 103 13 748). This structure compensates for thickness variations across the web width, prevents telescoping, and maintains consistent winding tension. With strong damping properties, wear-resistant surfaces, and customer-specific layer structures, MULTILAYER rollers deliver maximum process reliability and uniform pressure distribution – ideal for slitter rewinders, winding machines, and flying-splice rollers.

MITEX MITETEC

The development of MITETEC has made MITEX a leader in nonwoven roll coatings for a wide variety of production processes. The superior properties achieved by both the materials and processing at MITEX provide measurable benefits to the customer.

Improved squeezing results and defined oil application, together with reduced wear and the long service life of the coating, are significant improvements over conventional products.

Mitetec is successfully used, for example, in the steel and metal industry, in the automotive sector as well as in general mechanical engineering and pipeline production.